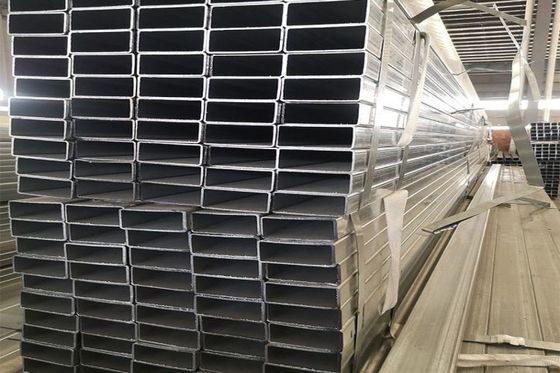

Product Description:

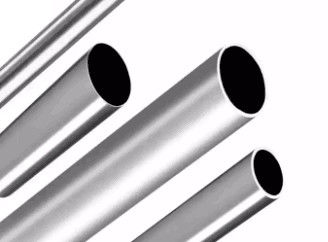

The Alloy Steel Tube is a crucial component in various industrial applications, known for its strength, durability, and resistance to corrosion. This Alloy Steel Seamless Tube is designed to withstand high temperatures and pressures, making it ideal for use in boiler systems, petrochemical plants, and other demanding environments.

With a production process that involves Cold Drawing, this Alloy Steel Boiler Tube is manufactured to precise specifications, ensuring uniformity and consistency in its structure. This method of production also enhances the tube's mechanical properties, making it suitable for critical applications where reliability is paramount.

Third Party Inspection by reputable organizations such as BV, SGS, and ASP further guarantees the quality and integrity of this Alloy Steel Tubular System. These inspections provide assurance that the product meets industry standards and specifications, giving customers confidence in its performance and reliability.

The Alloy Steel Tube is available with a choice of End finishes, including Plain Ends and Beveled Ends. The Plain Ends provide a simple and clean finish, while the Beveled Ends are designed for welding applications, ensuring a secure and leak-proof connection. This versatility in End options makes the tube adaptable to various installation requirements and preferences.

With a Width range of 20mm to 1800mm, this Alloy Steel Tube offers flexibility in sizing to suit different project needs. Whether for large-scale industrial systems or precision engineering applications, the wide range of Width options ensures that customers can find the right fit for their specific requirements.

Furthermore, the Alloy Steel Tube features Edge options of Mill Edge and Slit Edge, providing additional customization possibilities. The Mill Edge offers a smooth and uniform edge finish, while the Slit Edge provides a more tailored edge profile. Customers can choose the Edge type that best suits their installation methods and aesthetic preferences.

In conclusion, the Alloy Steel Tube is a versatile and reliable component that is essential for a wide range of industrial applications. Whether used in boiler systems, petrochemical plants, or other demanding environments, this tube offers exceptional performance and durability. With Third Party Inspection, Cold Drawn production, various End options, flexible Width range, and Edge choices, the Alloy Steel Tube provides customers with a high-quality solution for their tubular system needs.

Features:

- Product Name: Alloy Steel Tube

- End: Plain Ends / Beveled Ends

- Colour: Bright, shinny

- Edge: Mill Edge Slit Edge

- Width: 20mm-1800mm

- Advantage: Strong Corrosion-proof

Technical Parameters:

| Application |

Oil/Gas/Fertilizer |

| Marking |

As Required |

| Technique |

Hot Rolled, Cold Drawn |

| Surface |

Anodized, Brushed, Mill Finished, Polished |

| Colour |

Bright, Shinny |

| Production |

Cold Drawn |

| Third Party Inspection |

BV, SGS, ASP |

| Ends |

Plain, Beveled, Threaded |

| Width |

20mm-1800mm |

| Advantage |

Strong Corrosion-proof |

Applications:

Alloy Steel Tubes by JOHO are versatile and durable products that find application in various industries and scenarios. They are widely used in the construction of Alloy Steel Tubular Systems, Alloy Steel Line Pipes, and Alloy Steel Cylinders due to their exceptional properties and high-quality standards.

Manufactured in CHINA, these tubes are certified with ISO 9001, ensuring top-notch quality and performance. With a minimum order quantity of 1 TON, customers can easily procure these tubes for their specific requirements. The packaging details include Woodencase or Woven bag, providing secure transportation and storage.

JOHO Alloy Steel Tubes offer a quick delivery time within 40 days, making them a reliable choice for urgent projects. Customers can choose from payment terms like LC, TT, etc., adding flexibility to their purchasing process. The tubes come with Mill Edge Slit Edge, providing precise dimensions and a seamless finish.

These tubes are produced using advanced techniques like Hot Rolled and Cold Drawn, ensuring superior strength and durability. Additionally, Third-Party Inspections by BV, SGS, ASP guarantee the quality and reliability of the product.

One of the key advantages of JOHO Alloy Steel Tubes is their strong corrosion-proof properties, making them ideal for challenging environments and applications. The bright, shiny color adds a visually appealing aspect to the tubes, enhancing their overall aesthetic appeal.

Customization:

Customize your Alloy Steel Tube with JOHO's Product Customization Services:

- Brand Name: JOHO

- Place of Origin: CHINA

- Certification: ISO 9001

- Minimum Order Quantity: 1 TON

- Packaging Details: Woodencase/Woven bag

- Delivery Time: within 40 days

- Payment Terms: LC,TT,ect,.

- Technique: Hot Rolled, Cold Drawn

- Marking: As Required

- Colour: Bright, shinny

- Third Party Inspection: BV, SGS, ASP

- End: Plain Ends / Beveled Ends

Customization options available for Alloy Steel Heat Exchanger Tube, Alloy Steel Tubing, Alloy Steel Boiler Tube.

Support and Services:

Our Product Technical Support and Services for Alloy Steel Tube include:

- Expert guidance on installation and usage

- Troubleshooting assistance for any issues

- Recommendations for maintenance and care

- Regular updates on product enhancements and improvements

- Access to online resources and documentation for reference

Packing and Shipping:

Product Packaging:

The Alloy Steel Tube is carefully packaged in a sturdy cardboard box to ensure its protection during transportation. Each tube is wrapped in bubble wrap to prevent any scratches or damages. Additionally, foam padding is placed inside the box to provide extra cushioning.

Shipping:

We offer reliable shipping services to ensure the safe delivery of your Alloy Steel Tube. Our team will securely pack the tube and coordinate with trusted shipping carriers to deliver it to your designated address. You will receive a tracking number to monitor the status of your shipment.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!