Product Description:

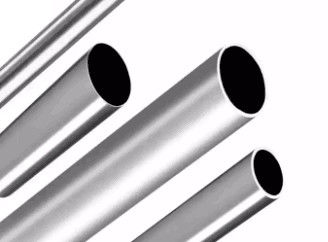

The LSAW Steel Pipe (Longitudinal Submerged Arc Welded Steel Pipe) is a high-quality piping solution widely used in various industrial applications, including oil and gas transportation, water supply, structural projects, and infrastructure development. With an outside diameter range from 355.6mm to 2320mm, these pipes are designed to meet diverse project requirements, offering a robust and reliable option for large-scale pipeline construction.

Manufactured in accordance with multiple international standards such as API 5L, EN10219, EN10210, and ASTM A252, the LSAW Steel Pipe ensures excellent mechanical properties, durability, and performance. These standards guarantee that the pipes meet stringent quality and safety benchmarks, making them suitable for critical applications involving high pressure, corrosive environments, and extreme weather conditions.

One of the key features of the LSAW Steel Pipe is its longitudinal welded line type, which provides superior strength and structural integrity. The longitudinal submerged arc welding process produces a consistent and high-quality weld seam, minimizing defects and enhancing the pipe’s overall reliability. This makes LSAW pipes an optimal choice for transporting oil, gas, and water over long distances, as well as for supporting heavy structural loads.

Surface treatment options for the LSAW Steel Pipe are diverse and tailored to meet specific environmental and operational demands. Customers can select from bare pipes, varnish coating or anti-rust oil, FBE (Fusion Bonded Epoxy), 3PE (Three-layer Polyethylene), 3PP (Three-layer Polypropylene), galvanized coatings, coal tar epoxy, and concrete coatings. These surface treatments provide excellent protection against corrosion, mechanical damage, and chemical attacks, significantly extending the service life of the pipes.

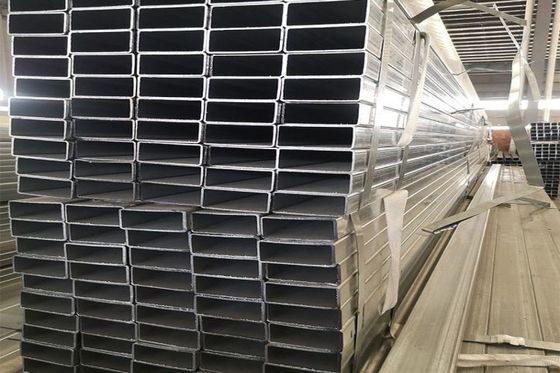

The galvanised steel pipe variant, in particular, offers enhanced corrosion resistance through a zinc coating that protects the steel substrate from rust and environmental degradation. This makes galvanised steel pipe an excellent choice for outdoor and underground applications where exposure to moisture and corrosive elements is common. The repeated emphasis on galvanised steel pipe highlights its importance and popularity in the market due to its reliable protection and cost-effectiveness.

To ensure the highest quality, the LSAW Steel Pipes undergo rigorous inspection procedures. These include hydraulic testing to verify the pipe’s strength and pressure resistance, eddy current testing to detect surface and subsurface defects, radiographic testing (RT) for weld integrity, ultrasonic testing (UT) for wall thickness and flaw detection, and third-party inspections for unbiased quality assurance. Such comprehensive inspection protocols guarantee that every pipe delivered meets or exceeds customer expectations and industry standards.

In summary, the LSAW Steel Pipe is a versatile and dependable product designed to meet the demands of modern infrastructure and industrial projects. Its wide range of outside diameters, compliance with international standards, variety of protective surface coatings, and thorough inspection methods make it a preferred choice for engineers and project managers worldwide. Whether you require a galvanised steel pipe for corrosion resistance or a pipe with specialized coatings for harsh environments, the LSAW Steel Pipe offers the performance and durability needed to ensure project success.

Technical Parameters:

|

Surface Treatment

|

Bare, Varnish Coating/Anti Rust Oil, FBE, 3PE, 3PP, Galvanized, Coal Tar Epoxy, Concrete Coating

|

|

Transport Package

|

Black Paint, Bevel Send, End Caps

|

|

Steel Grade

|

API 5L: GR B, X42, X46, X56, X60, X65, X70; ASTM A53: GR A, GR B, GR C

|

|

Welded Line Type

|

Longitudinal

|

|

Usage

|

Structure Pipe, Pipe Piling Construction

|

|

Outside Diameter

|

355.6mm - 2320mm (including sizes like 2 inch galvanized pipe, 24 inch steel pipe)

|

|

Standard

|

API 5L, EN10219, EN10210, ASTM A252 Etc

|

|

Inspection

|

With Hydraulic Testing, Eddy Current, RT, UT or Inspection by 3rd Party

|

|

Wall Thickness

|

5mm - 50mm

|

Applications:

The JOHO LSAW Steel Pipe, originating from China and certified with ISO 9001, is a highly reliable and versatile product widely used in various industrial and construction applications. With an outside diameter ranging from 355.6mm to 2320mm, this steel round tube is designed to meet the demanding requirements of structural and pipe piling construction projects. The steel grades available, including API 5L GR B, X42, X46, X56, X60, X65, X70, and ASTM A53 GR A, GR B, GR C, ensure excellent mechanical properties and durability, making the LSAW steel pipe ideal for heavy-duty applications.

In infrastructure development, JOHO LSAW steel pipes are commonly used for bridge construction, building frameworks, and large-scale pipeline installations. Their longitudinal welded line type provides enhanced strength and stability, crucial for supporting heavy loads and withstanding harsh environmental conditions. The steel round tube’s surface treatment options, such as bare, varnish coating, anti-rust oil, FBE, 3PE, 3PP, galvanized, coal tar epoxy, and concrete coating, offer superior corrosion resistance, extending the service life of the pipes in various climates and soil conditions.

The 2 inch galvanized pipe variant of the JOHO LSAW steel pipe is particularly popular in applications where corrosion resistance is critical, such as water supply systems, gas pipelines, and outdoor structural frameworks. Its galvanized coating offers robust protection against rust and environmental damage, making it suitable for both urban and rural construction projects. Additionally, the 2 inch galvanized pipe is frequently used in agricultural irrigation systems and industrial facilities, where durability and longevity are key considerations.

JOHO’s LSAW steel pipes are also favored in foundation engineering, particularly in pipe piling construction, where their large diameter and structural integrity help secure building foundations and prevent soil erosion. With a minimum order quantity of just 1 ton and competitive pricing ranging from USD 650 to USD 1500, these pipes provide cost-effective solutions without compromising quality. Customized packaging is available based on customer requests, ensuring safe delivery within 30 days. Payment terms such as LC and TT provide flexible purchasing options for clients worldwide.

Overall, the JOHO LSAW steel pipe is an excellent choice for applications requiring high-strength, corrosion-resistant steel pipes. Whether used as a steel round tube in structural construction or as a 2 inch galvanized pipe for corrosion-prone environments, this product meets the rigorous demands of modern engineering projects, backed by stringent quality certifications and reliable manufacturing standards.

Packing and Shipping:

Our LSAW Steel Pipes are carefully packaged to ensure maximum protection during transportation and handling. Each pipe is coated with a protective layer to prevent corrosion and wrapped with anti-rust paper or plastic film. The pipes are then bundled securely with steel straps and supported by wooden blocks to avoid any movement or damage.

For shipping, LSAW Steel Pipes are loaded onto containers or flatbed trailers using cranes and other heavy-duty equipment. We ensure that the pipes are firmly secured to prevent shifting during transit. Our logistics team coordinates with reliable carriers to guarantee timely and safe delivery to your specified destination.

FAQ:

Q1: What is the brand name of the LSAW Steel Pipe?

A1: The brand name of the LSAW Steel Pipe is JOHO.

Q2: Where is the LSAW Steel Pipe manufactured?

A2: The LSAW Steel Pipe is manufactured in China.

Q3: What certification does the LSAW Steel Pipe have?

A3: The LSAW Steel Pipe is certified with ISO 9001.

Q4: What is the minimum order quantity for the LSAW Steel Pipe?

A4: The minimum order quantity for the LSAW Steel Pipe is 1 ton.

Q5: What are the payment terms available for purchasing the LSAW Steel Pipe?

A5: The payment terms available include LC (Letter of Credit), TT (Telegraphic Transfer), and other methods.

Q6: What is the typical price range for the LSAW Steel Pipe?

A6: The price of the LSAW Steel Pipe ranges from USD 650 to USD 1500, depending on specifications and quantity.

Q7: How is the LSAW Steel Pipe packaged for delivery?

A7: Packaging details are customized and done according to customer requests.

Q8: What is the delivery time for the LSAW Steel Pipe after placing an order?

A8: The delivery time is typically within 30 days after the order is confirmed.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!